If you click on the tab at the top left hand side of the home page you get taken to the “Weather” page where there is a link to my other website displaying current weather data at Dengemarsh. The “system” for collecting the data – Windspeed, direction, pressure, temperature, humidity, ranfall etc. is a Technoline WS2350. This is similar to the La Crosse WS2310.

I first set the system up in 2007. The Weather vane and anemometer sits on top of a 9m mast – well clear of the turbulent effects of nearby buildings. The website is very popular with the wind and kite surfers who frequent the nearby beaches at Greatsone and Camber. They like it apparently as it gives very accurate windspeed and direction information – important so I am told for maximum enjoyment of the sport! It is also heavily accessed by fishermen who fish off of Denge beach and Dungeness Point. I must point out at this point that I don’t enjoy or indulge in any of the above activities!

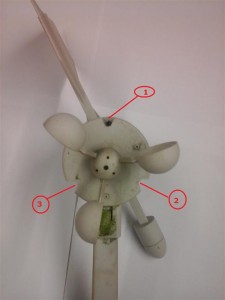

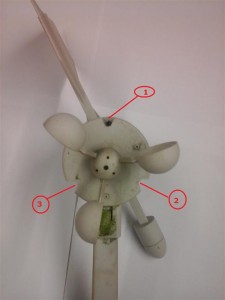

The original anemometer had a small propeller underneath attached to the weather vane which kept it facing into the wind. This lasted about 12 months and was replaced by the more traditional and more accurate “three cups” design. The first one of these lasted around 3 years before I noticed the wind direction “sticking” and the windspeed grossly under reading. Having taken the mast down I quickly ascertained that the “bearings” were worn and decided to get a new LAC TX-20 Windspeed and Direction Sensor. This was duly fitted and lasted a similar time to the first – we are near the coast its windy most of the time, the wind is also salt laden when from the southwest so the short life is not overly surprising on a relatively low cost system (The whole station currently retails at £110). So this time I decided to strip the unit down and see if it could be repaired, Also the sensor were showing out of stock every where I looked.

Step 1. Remove the sensor from the mast – lower the mast, undo the U clamp holding the sensor to the mast and disconnect the cable, then escape to the warmth of indoors!

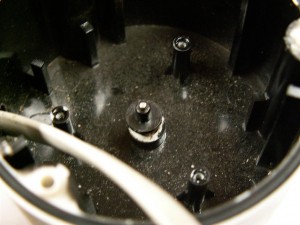

Step 2. Remove the 3 screws seen from the underneath.

Step 3. carefully separate the direction indicator top half from the anemometer bottom half.

There is a small, square LED that is a snug fit into a plastic lightguide, It does just slide out Just “wiggle” the top and bottom halves gently separating them and it will come out.

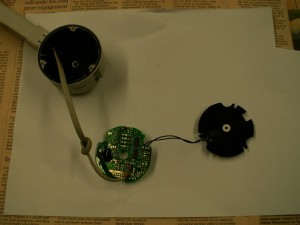

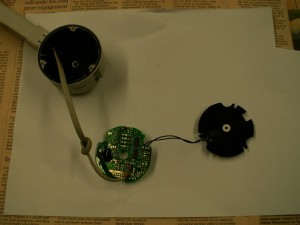

Step 4. Gently lever out the PCB, be careful as there are two thin black wires attached to the underside of the PCB that connect to the magnetic sensor that detects the windspeed.

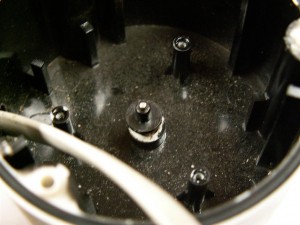

Step 5. Finally you will be able to see a black plastic base plate, the one in the picture has the wires disconnected. Remove the three screws and carefully lever the base plate out, you can gently lift on the legs of the magnetic sensor, hold the data cable out of the way.

Step 6. You can now see the top bearing of the anemometer. The bearings are really small roller bearings. Lift off the bearing from the spindle.

Step 7. Next CAREFULLY ease the small round magnet off of the plastic carrier. The magnet is quite soft and will break easily.

Step 8. Now using the blunt end of a screw driver (i.e the handle) carefully push down on the exposed spindle end whilst supporting the casing. The spindle is a push fit through the lower bearing and the plastic magnet carrier. Once the spindle has started to move you should be able to ease the plastic carrier upwards and remove it from the spindle. The spindle should then be easy to pull out from the lower bearing. Once removed tip the housing upside down to let the lower bearing drop out. You will be left with 5 components, Cups and spindle, lower bearing, plastic magnet carrier, magnet, upper bearing.

Ok that’s everything dismantled. Now when you examine the parts you will probably be ably to see the wear on the bearing cup for the wind direction sensor. The picture below shows the wear I found, it was the same on both units is dismantled.

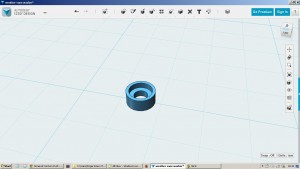

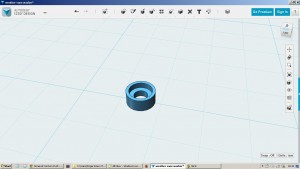

There are various options for repair. I chose to remove the remaining “wall” with a knife and using my 3D printer make a small stepped washer to fit over the brass bearing. (See my 3D printer post to see what I am talking about!). The whole process of making two washers, one for each of my sensor units, took about 25 mins, that was measuring, drawing the 3d model, and printing two repair pieces.

The stepped washer was a good fit and snapped over the remaining stub needing no glue – quite satisfying! It can’t come off as the spindle from the vane will keep it in place.

Rest of wall removed

Stepped washer in position

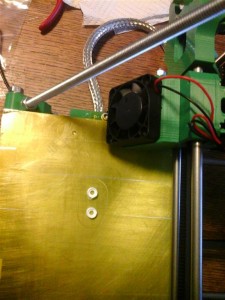

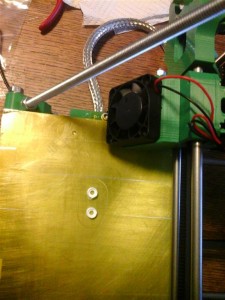

Now onto the anemometer. The problem here seemed to be the excessive play around the roller bearings. This allows the spindle excessive sideways movement leading to the hub of the plastic cups rubbing on the body of the unit. This obviously causes a lot of drag affecting the wind speed readings. It appears that the bearing outers were free to rotate in the plastic recesses designed to locate them. Over time these have worn. I took the easy way out and used the hot tip of my soldering iron to melt the inside of the recess causing lots of little ribs. I the pressed the bearings back into the plastic with the iron. Care is need to ensure the bearings are centred within the moulding. This done it was simply a matter of reassembly.

Ready for reassembly. (black wires soldered back onto the sensor)

It does not matter which way round the black wires go. Check both ends before you put it back together, the wire is very thin and easy to break, better to remake the joints at both ends and be sure they are OK than put it all together and find out one has broken on reassembly.

To reassemble first slide the spindle of the cups through the lower bearing – which should be securely held in the moulding.

Next carefully press on the plastic magnet carrier, make sure you get it the right way up. Press it on so that the spindle just pokes through. At this stage I put a couple of drops of very light sewing machine oil on the each of the bearings – I suppose you could use WD40 if you are a fan (bear in mind WD40 is a water dispersant hence the initials WD and NOT a permanent lubricant).

The place the magnet over the carrier.

The place the base plate into the moulding, make sure you get it round the right way and make sure it is full seated on the three pillars. Whilst holding it all together squeeze the cups up wards so as to push the spindle through into the upper bearing. You want to make sure it is pushed up sufficiently to remove most of the play but not too much so that it rubs on the moulding. Check it is free to rotate. If all is well fit the three screws. If not pull it apart again and find out why not. The crucial thing is to make sure both bearings are secure and do not have any free play in the housing which causes side ways movement of the spindle allowing the cups to rub.

Next put the PCB in place, again watch the orientation.

Now you can fit the top part – first check the rubber O ring seal is still in place around the edge of the lower part. Make sure you guide the LED into the slot in the light guide in the upper part. Also make sure the top part is correctly aligned – East should face away from the mounting arm – there is a little raised pip to align on the upper and lower mouldings as shown below.

Finally refit the last three screws to hold the whole lot together.

A quick check to make sure it all works before refitting to the mast and hopefully that is it for another couple of years.

Weather website is here if you are interested:

www.thejonesgroup.co.uk

I’ll add more info on the station later – such as how to fix the rain gauge, and how to add an external aerial to improve wireless range.